PRedicting wear of thErmally sprayed abradable sprayable CoatIngs for compressor SEals

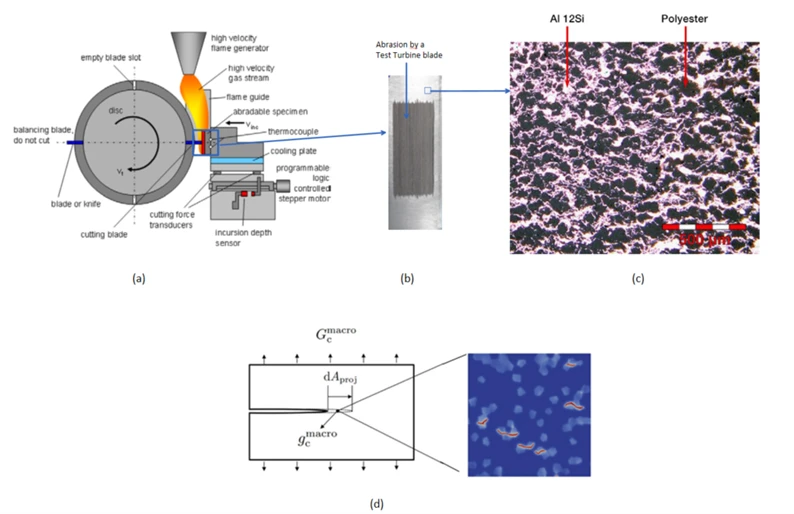

Abradable coatings in the axial compressors of turbomachinery are designed to minimize the clearance between the rotor tip and stator without damaging the rotor (turbine blade). This leads to improved efficiencies of the compressors; however, intermittent wear and abrasion events are prominent during operating surges. The thermomechanical behavior of these abradable sealing materials plays a central role in the wear of the coating. This is to be investigated using efficient modeling approaches, whereby the role of its heterogeneous microstructure will be taken into account. Within the framework of this project, firstly a macroscale FEA (Finite Element Analysis) model would be developed. Utilizing the results of this component scale model - a micro thermomechanical FE model would be developed to carry out damage analysis. The damage at the microscale will be analyzed based on phase field modeling approach, in which cracks are continuously represented with a field variable (crack phase field). These modelling approaches capture different scales and will be compared and possibly coupled/combined to create a novel simulation workflow for predicting the wear of abradable coatings with the highest possible accuracy at an acceptable computational cost.

Key objectives:

Investigations of the wear/incursion mechanics of abradable coatings to enhance its understanding through computational simulations and experiments.

Predicting the damage behavior of the abradable coatings under varying operational variables and phase-specific material parameters.