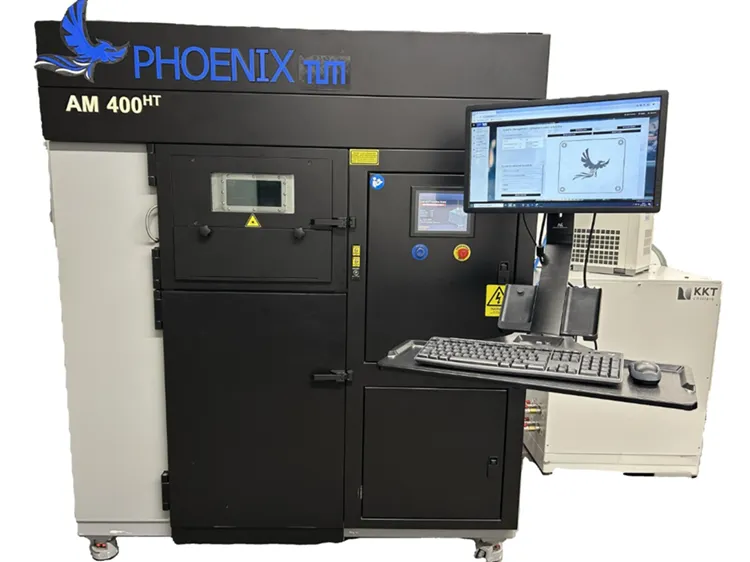

The potential of powder bed fusion of metals using laser-beam (PBF-LB/M) is currently constrained by outdated software and limited control options. This results in systems relying on fixed and untailored process parameters, despite advanced hardware capabilities. Furthermore, this prevents the inclusion of state-of-the-art monitoring systems, which hinders research flexibility and slows technological progress. Project Phoenix addresses this gap by combining state-of-the-art hardware with a fully customizable control system, enabling unprecedented process freedom. The underlying system is based on an industrial machine platform, which enables the combination of high-performance hardware infrastructure with an open and flexible software architecture. This industrial foundation not only ensures high process stability but also facilitates the transfer of research-driven innovations into real-world production environments. By integrating the Autodesk Machine Control Framework, Phoenix allows complete access to process parameters and the integration of monitoring and control systems, transforming a conventional PBF-LB/M machine into a platform for cutting-edge research. This open and modular system facilitates novel process strategies, such as tailored and controlled scan patterns to mitigate defects and increase build quality. The project thus acts as a pathfinder for transforming outdated infrastructure into advanced research-oriented manufacturing tools, unlocking new opportunities for material and process innovation in laser-based additive manufacturing.